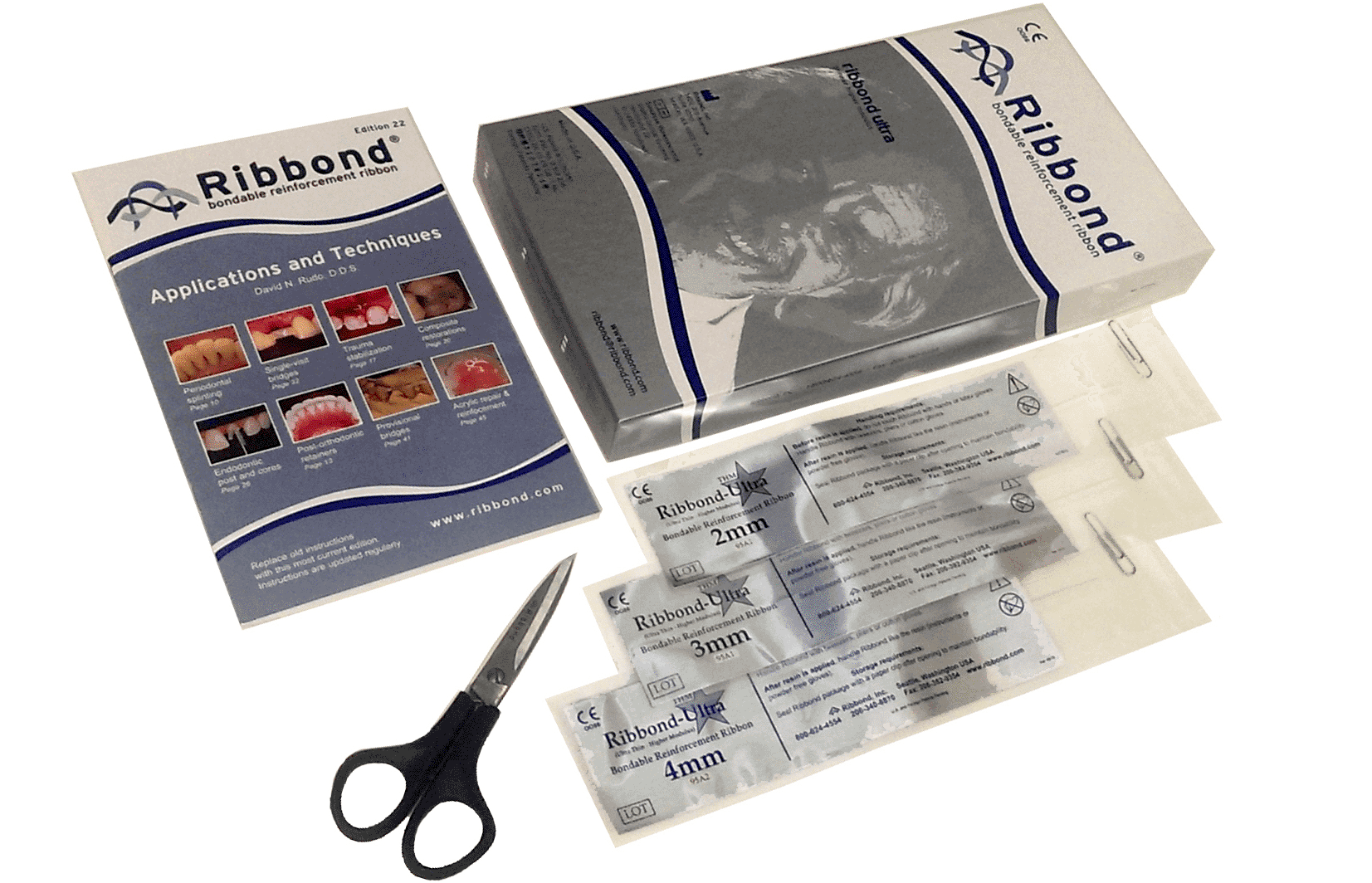

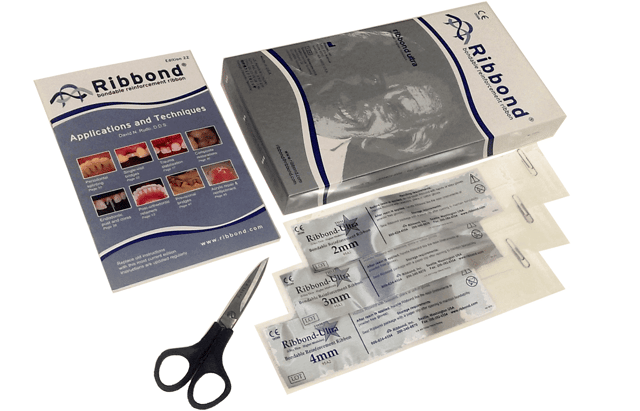

Ribbond ULTRA Starter Kit, 68mm plus Scissors

Product Code : RIBASTU

Brand : RIBBOND

Login to View Price

Product Code:RIBASTU

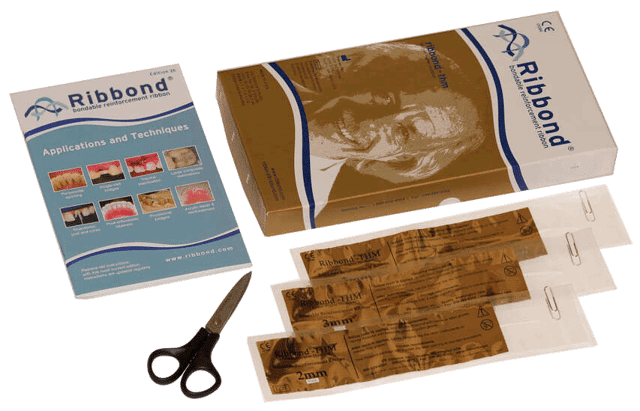

Ribbond ULTRA Assorted Starter Kit - 3 Sizes plus Scissors

The thinnest of all Ribbond fiber reinforcement ribbons, (0.12mm thick).

Product Information

| # | Attribute | Value |

|---|---|---|

| 1. | Pack Type | Kit |

| 2. | Supplier Code | ASTU |

| 3. | Function | Fibre Reinforcement Material |

| 4. | Pack Contents | "Three 22 cm long pieces of Ribbond (Enough material for approximately 21-30 cases) Special Ribbond scissors (Note: Normal scissors will not cut Ribbonds super tough bullet proof fibers) Easy to understand instructions Dead soft tinfoil for measuring." |

| 5. | brand | RIBBOND |

Starter Kit Includes

- Three 22 cm long pieces of Ribbond

(Enough material for approximately 21-30 cases) - Special Ribbond scissors

(normal scissors will not cut Ribbond’s super tough “bullet proof” fibers) - Easy to understand instructions

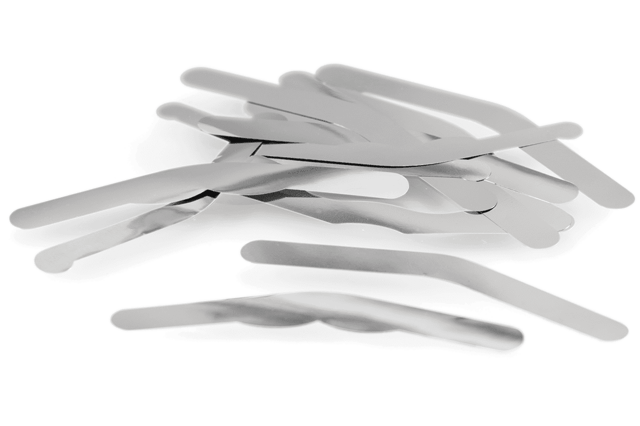

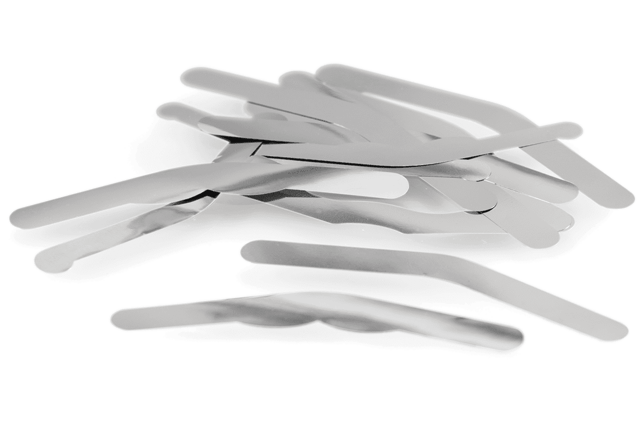

- Dead soft tinfoil for measuring.

About Ribbond Fibers

Ultra-high strength fibers

Ribbond is made from the same ultra-high molecular weight polyethylene fibers used to make bulletproof vests. These fibers far exceed the breaking point of fiberglass and are so tough that specially made scissors are required to cut them. Unlike Kevlar, Ribbond's fibers absorb less moisture than the dental resins.

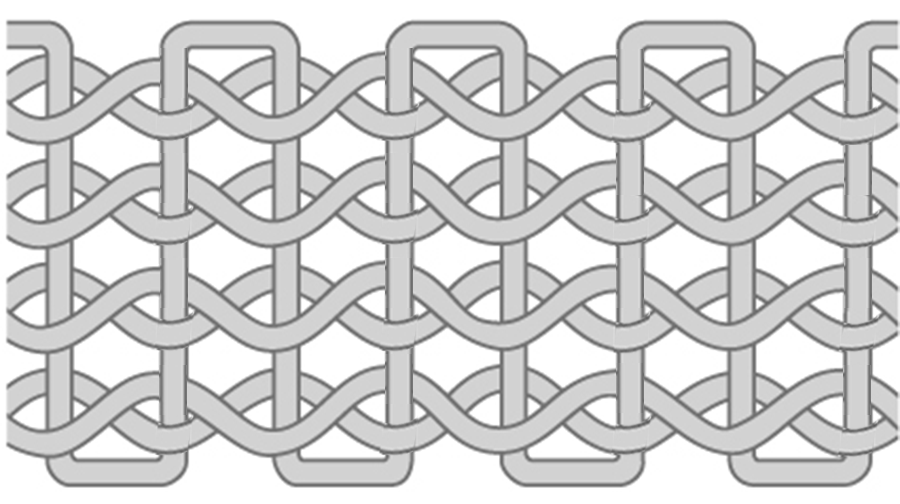

Patented Leno Weave = Superior Manageablilty

The key to Ribbond's success (and what distinguishes Ribbond from the other fiber reinforcements) is its patented leno weave. Designed with a lock-stitch feature that effectively transfers forces throughout the weave without stress transfer back into the resin, Ribbond's weave also provides excellent manageability characteristics. Having virtually no memory, Ribbond adapts to the contours of the teeth and dental arch. For example; when making a periodontal splint, Ribbond tucks in interproximally without rebounding. In addition, unlike loosely braided or bundles of unidirectional fibers, Ribbond does not spread or fall apart when manipulated.

Since fiber reinforced resin structures derive their strength primarily from making laminates, high manageability and lack of memory is essential for close and accurate layering of the fibers. Inaccurate fiber placement results in voids or excessive composite on the tensile side of the fibers that will be prone to fracturing.

Ribbond's Patented Cross-Link Lock-Stitch Leno Weave.

No memory + Does not unravel = Easy placement.

Bondable

Ribbond is cold-gas plasma treated and will bond to any dental composite resins. Magnified 110,000 time, SEM's demonstrate complete incorporation of the resin to Ribbond's fibers (note lack of voids). Forces within the resin are easily transferred to the fibers insuring that the Ribbond is an integral strength member of the prostheses.

Biocompatible

Ribbond's fibers are the standard in biocompatibility. The same material is also used in the construction of artificial hip and knee joints. Unlike fiberglass, if at anytime the Ribbond is cut into with a rotary instrument, the resultant particles and exposed fibers will not be a biocompatibility risk to the patient.

Esthetic

Ribbond is translucent, practically colorless and disappears within the composite or acrylic without show-through. Not only does Ribbond offer excellent esthetics, its translucency also allows the use of light cured composites.

Versatile

The unique combination of strength, esthetics and bondability allows Ribbond to be used for many different applications. Ribbond bonds to both composite and acrylic giving you a material with multiple uses.

Indefinite Shelf Life

Ribbond has an indefinite shelf life. This minimizes waste, which is great for dentists who only occasionally use Ribbond.